Published on 2022/08/26 Research powered by Mightex’s Polygon1000

Check out this Polygon 1000 customer highlight focused on Mark Mittmoen. Mark is a doctoral student in Dr. Ofer Kedem’s lab at Marquette University. He uses UV and visible light with the Polygon1000 to create highly complex photopatterns. Mark recently published his work on this topic in ACS Applied Materials & Interfaces.

Introduction

Molecular printing, whereby molecular substrates are deposited onto a surface, has developed extensively in recent years. This allows researchers to modify the chemical properties or surfaces to sculpt their interactions with surrounding molecules and nano- or micro-scale objects, such as cells. This technique is particularly important for biological applications such as the development of biosensor arrays. While significant advances have been made in recent years with such photolithography techniques, some problems remain, such as low throughput and non-uniformity.

To address these issues, Mark and colleagues used the Mightex Polygon1000 to produce high-quality patterns using maskless photolithography for fast and easy prototyping. Their technique included the use of photopattern molecules, such as fluorescent dyes, on silanized surfaces. Silanes form self-assembled monolayers on glass, and by choosing silanes with different tailgroups, they are able to obtain different surface functionalities.

In their recent work, the group used thiol tailgroups, and projections of UV (365 nm) patterns on the glass substrate, while it was submerged in a solution of photoinitiator and alkyne-terminated molecules. The UV light was then able to catalyze the thiol-yne “click” reaction to attach the alkyne-functionalized molecules to the surface.

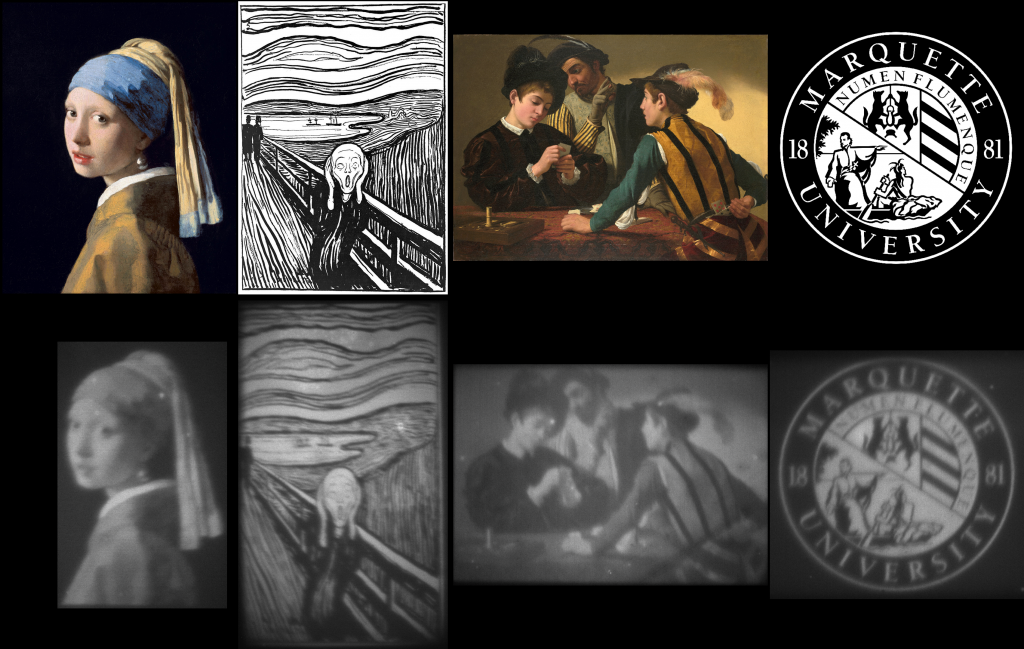

By projecting different patterns, they control exactly how and where molecules are attached, and so can produce monolayers of complex shapes. Furthermore, they can obtain monolayers with partial coverage – by breaking down a grayscale image into a series of different black and white images. This then allows Mark and his colleagues to individually control the exposure time at each pixel, and then tune the density of deposited dye molecules at each position. This is seen in the below image of 4 examples.

Figure 1: The top row contains the original patterns, and the bottom row displays the captured fluorescence images from the fluorescein derivative dye (FAM alkyne, 5-isomer) that was attached to the patterned location, observed with 455 nm light. From left to right, the images are: 1) “Girl with a Pearl Earring” by Johannes Vermeer, 2) black-and-white version of “The Scream” by Edvard Munch, 3) “The Cardsharps” by Michelangelo Merisi da Caravaggio, and 4) the seal of Marquette University. Each image in the figure has an area of only 0.48 mm^2.

Methods

Patterning using this thiol–yne click reaction is widely applicable for biomolecules. This is useful as it begins with easily obtained reagents and standardized alkylation procedures. However, the technique requires some optimization . To obtain higher quality patterns, the Kedem group have also used more recently developed surface modification substrates coated with different silanization agents: mercaptopropyltrimethoxysilane (MPS), and mercaptopropylsilatrane, a molecule previously reported to form smoother monolayers.

Findings and Conclusion

Mark and his colleagues are currently pursuing the ability to photopattern appropriately functionalized gold nanoparticles in an arbitrary gradient using this technique. Their long-term interest is to create surface-based chemical reaction networks, which interact with the environment and conduct multi-component reactions on surfaces. For this purpose, we need to selectively localize different molecules in specific locations, creating the need for developing the photopatterning capability detailed here.

Catherine Thomas, PhD Senior Liaison and Development Scientist at Mightex

To read the full publication, please click here.