Polygon for Photopatterning:

Facile Maskless Lithography Experiments with Any Microscope

Facile Maskless Lithography Experiments with Any Microscope

Spatial patterning of light is a powerful technique with broad applications in cell biology, chemistry, material science, biomedical engineering, and more. Light-sensitive materials can be etched and carved with high precision using the appropriate light source and pattern to engineer unique cellular microenvironments, surface topologies, and complex material architecture.

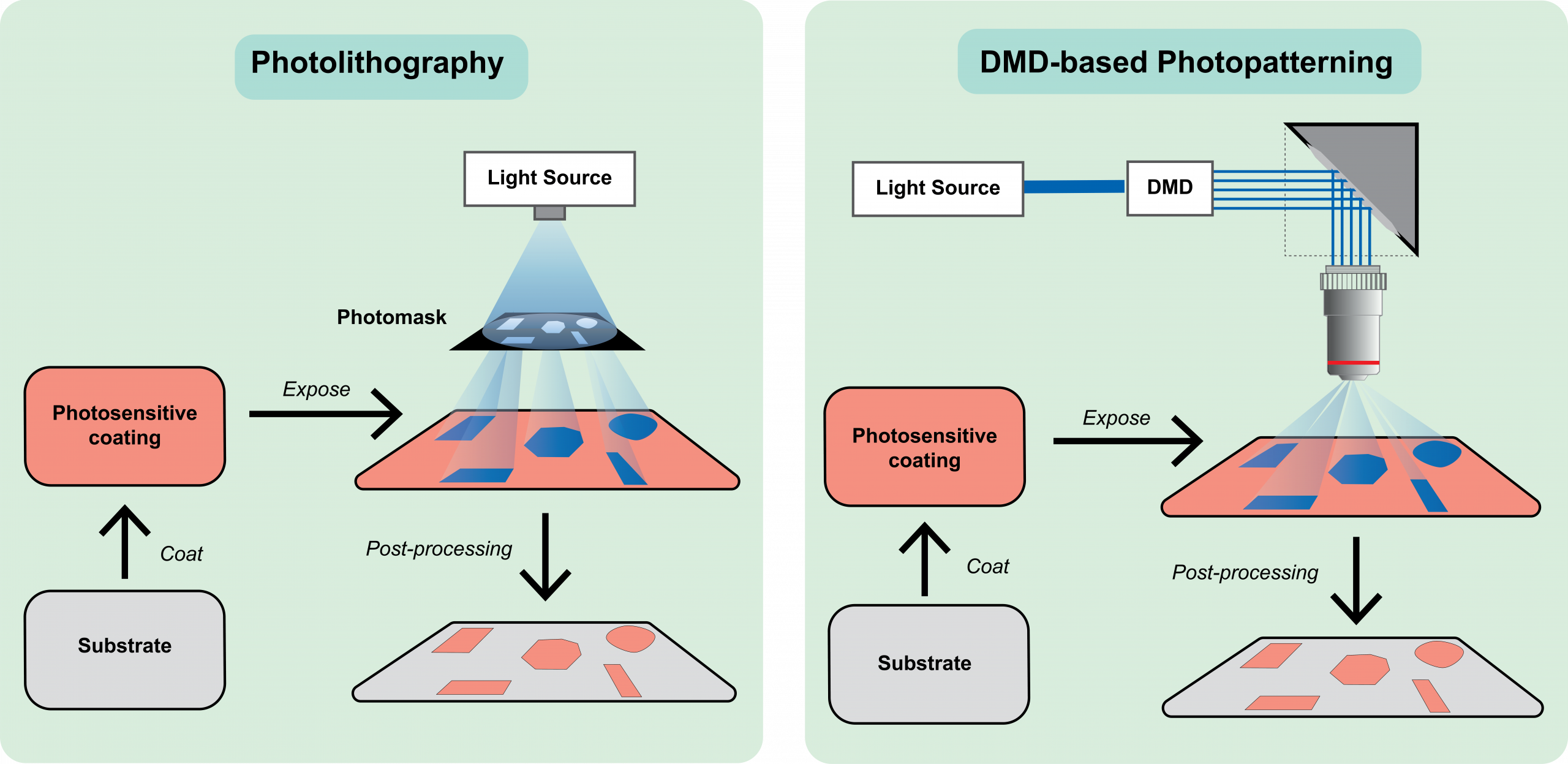

This approach of micro/nano-engineering was traditionally achieved using photolithography techniques, which can provide sub-micrometer resolution and are commonly used in the production of microchips. However, this procedure requires expensive clean-room environments and equipment along with highly experienced personnel. Most importantly, the need for a photomask to create patterns can be costly and time consuming for iterative design, presenting a significant limitation on this approach.

Maskless techniques aim to overcome this limitation by replacing the physical photomask with a digital one through spatial light modulators. Since this is achieved without physical contact with the sample, it requires less sample processing, and it is an ideal technique for rapid prototyping and high iteration testing. It is also advantageous for biological applications, where sterility of the sample may be important. A prominent example of this is light modulation using digital micromirror devices (DMD), which can be integrated into microscopes and other imaging apparatus to provide sub-micrometer resolution, high-speed pattern switching, and compatibility with a wide range of applications

DMD-based systems provide great resolution, speed, and compatibility at a reasonable cost for rapid R&D and wide-spread implementation of photopatterning to advance research and knowledge. Among these systems, Mightex’s market-leading Polygon 1000 Pattern Illuminator provides a powerful and easy to use module for patterning with seamless integration into any microscope setup to fit any lab. It maximally harnesses DMD technology to achieve optimized transmission efficiency, excitation power, and signal to noise ratio to illuminate and create features of any size or shape. The Polygon 1000 comes in different versions to accommodate a wide range of LED and laser illumination sources providing versatility for different projects.

When selecting the ideal system for your application, some important factors to consider are resolution, speed, compatibility, and cost. For applications involving small and highly intricate pattern features, Mightex’s engineers have designed an ultra-high contrast (UHC) version of our Polygon1000. The Polygon UHC delivers exceptional precision by significantly improving contrast between illuminated and non-illuminated areas, enabling sharper feature definition and improved resolution. Overall, DMD-based patterning provides great value and versatility for most biomedical applications, providing a user friendly system for iterative and high-throughout research needs.

To learn more about the Polygon and its features, click here or reach out to our customer support team.

Michael Yitayew, PhD Applications Scientist at Mightex